Blog

Meet the Sales Team at Ambi Robotics: Helping Shippers Handle More

The persistent surge in global parcel flow poses a formidable challenge for shippers and their warehouse teams, prompting an urgent quest for immediate and effective solutions to manage the escalating ecommerce volume within the broader supply chain.

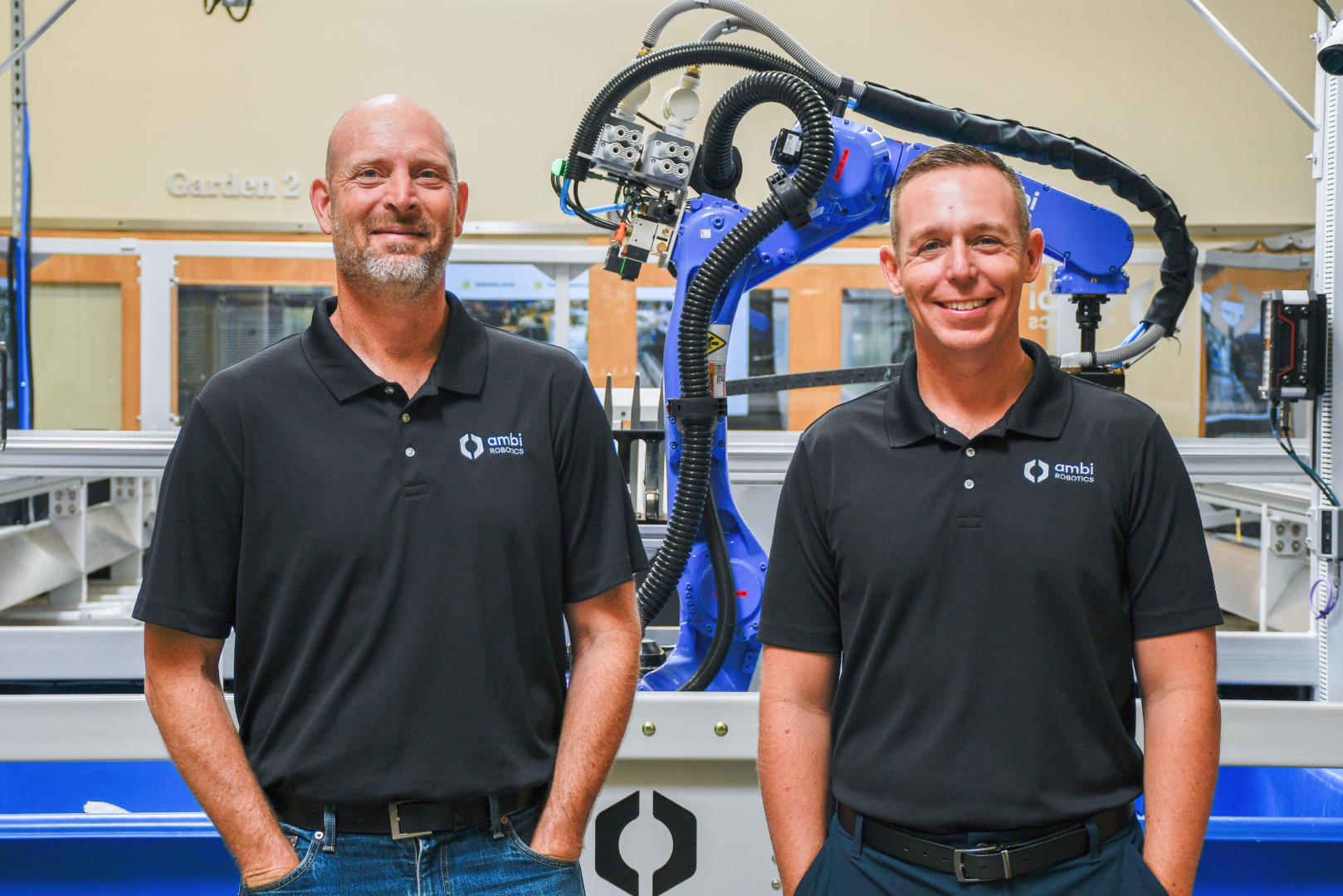

Two key members of the Ambi team—the VP of Sales, Joe Mahaney, and the Director of Sales, John Zaremba—are addressing this challenge head-on. In our conversation with Joe and John, we delve into Ambi Robotics’ unique approach to providing a solution that not only meets but surpasses the demand of the current supply chain while empowering warehouse workers to handle more.

How do solutions from Ambi Robotics contribute to improving supply chain operations?

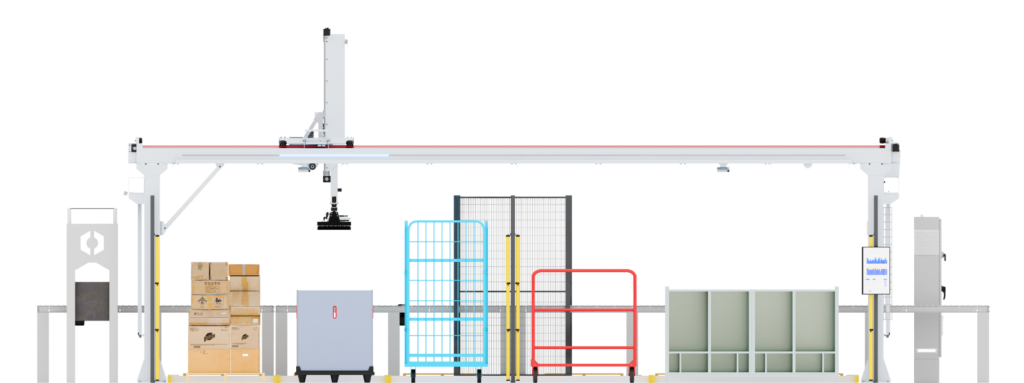

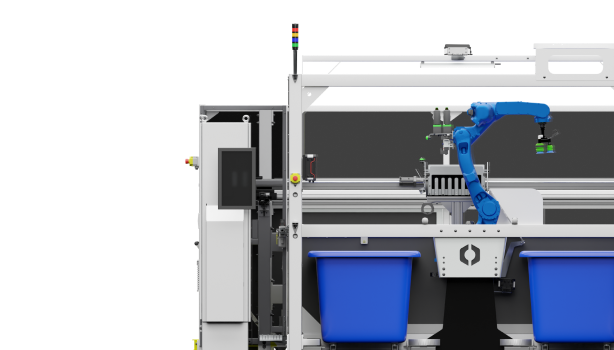

Joe: Ambi Robotics fits into a narrow but essential part of these companies that sort packages. Our systems efficiently do a job typically done by people—taking packages, reviewing them, and placing them in receptacles all day. While this process happens automatically for associates, it is done more accurately and faster when associates and robotic systems work in tandem to complete the work.

John: One of the many nice things about robotic systems is that they can run almost all day, every day. Depending on a warehouse’s operational needs, the systems can boost the efficiency of the people working with them. If you’re talking about getting more items through safely and at greater volumes, our systems help with those supply chain operations.

Have you seen this contribution in person? How have you seen this come to fruition?

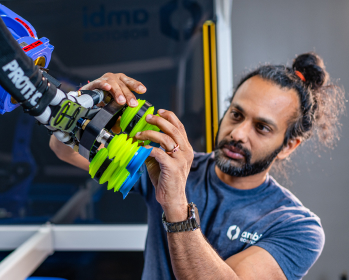

John: Once, an associate shared, “I used to do this all the time, spending my days putting packages in sacks. Now, I instruct the robot to perform the task.” There’s a particular pride in operating these robots for such a task. As you observe from a distance, you realize the tiresome nature of the job, the challenges it poses, and the intense concentration required to execute the job correctly. Being able to step back and let a machine handle some of these mundane tasks while providing guidance is genuinely great to see.

Joe: In my experience, the initial impression upon entering one of our sites is notable. Our systems stand out, and the mechanical equipment within the systems shines. It’s fantastic to see people buzzing around the systems and interacting with them. The most significant impact I have experienced is hearing from the associates on-site, who love working with the systems and share stories of their work. Our partners appreciate having the systems, particularly those previously performing manual sorting tasks. Witnessing individuals transition to more fulfilling roles is the biggest success story I’ve experienced numerous times while traveling to different sites throughout the past year.

How do you approach collaborating with customers to tailor solutions to meet their specific requirements and maximize their ROI?

Joe: I see our job as understanding the process to enable our company to do everything correctly so that when we visit a potential customer, we are as prepared as possible. The technology is what it is – it will do what it will do. We help customers build out their business case. We’re aligning a need with what we can provide and demonstrating the value of our systems along the way.

John: We work collaboratively to determine where our systems can integrate into current operations, how the robotic systems will improve operators’ daily experiences, and the throughput increase a business will experience. This includes the rate at which the robotic system will increase throughput, how operator sorting efficiency will increase, and other relevant metrics important to the customer. It’s our goal to ensure potential customers are aware of the benefits of deploying Ambi Robotics systems in their operation.

It’s important to recognize the approach and understanding of holding two-way conversations with our partners. Ultimately, what does a partnership with Ambi Robotics look like?

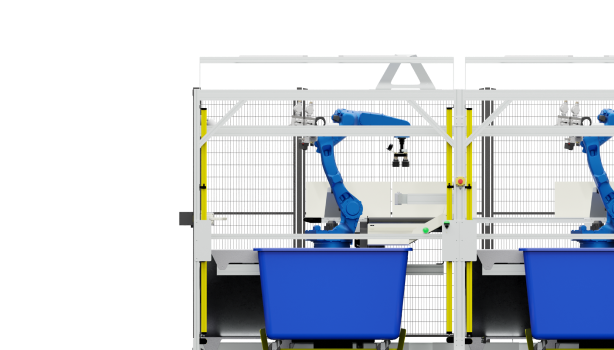

John: Our Ambi product engineers visit customer sites regularly to observe, tweak, and improve the systems’ performance. We collaborate with the warehouse teams to see how they work with our robotic systems and determine changes. For example, we want to understand if a new product is introduced to the facility or what happens when a shift changes. We know all our systems’ locations and work closely with the personnel at each site to ensure our systems perform flawlessly. Our partnership includes 24/7 support.

Joe: Once a customer deploys one or more of our robotic systems, our operations and customer success teams take over, and this is their time to shine. John and I are constantly engaged with our customers, but our teams do a lot of the heavy lifting and daily communication to ensure we are getting to know their business and people exceptionally well. Our customers feel heard and understood.

What makes Ambi Robotics’ sales approach unique when it comes to offering AI-powered sorting solutions to customers?

John: We spend a lot of time trying to understand the customer’s current process and what they’re trying to achieve by potentially changing that or adding technology, especially when it comes to dynamic and constantly changing AI-powered technology. We communicate the customer’s goals back to our team and collectively determine the best way to use our technology to help provide the solution that the customer is seeking.

In your experience, where have you seen an interest in the AI we utilize?

John: Operators or facility managers don’t necessarily put a lot of stock into the underlying technology that is allowing them to complete their work. Their primary focus is whether it worked all day and if the desired throughput was achieved. Many operators care when they see that the system is working on day one, and that’s due to the AI. Later on, on day 120, the system performs at an even greater level because of the technology that powers it.

Joe: With AI, the product continues to improve over time and adjust itself to your changing business. It’s difficult to explain to people who haven’t experienced it. I didn’t understand until I saw it happen myself over time.

What sets Ambi Robotics apart from other companies in the robotics and automation space, and how does that benefit our customers?

Joe: We have a large deployment of robots in the field, and they work together to deliver feedback to our team to make continuous improvements. The consistency has provided us with valuable feedback to continuously improve sort plan optimization, general software improvements, operator input on improving the hardware, and more. Due to this, our systems have been tried and are true. When we deploy a new system, it is deployed extremely quickly, with minimal kinks to work out. The onboarding experience is much smoother compared to some competitors. They have great technologies, too, but we stand out in this aspect.

Additionally, our support structure, including our 24/7 customer support team and dedicated team of robot technicians, is superior thanks to our extensive experience and range of robots. This is a significant differentiator for us. Over the past 18 months, I’ve watched how our robots continue to improve and adapt in real-time, thanks to their extensive experience and time in operation. I’ve started to refer to our systems as “sorters,” akin to a trusted secondary source. It’s not a new AI concept; it’s a reliable sorter that delivers as expected.

John: I believe that our differentiator is that we’re very focused, which lends itself to polished products. The lack of distraction lets us delve into experimenting with bettering those products, and we’re adventurous. We like to experiment and push boundaries to ensure we deliver the most tailored solutions that help meet our customers’ needs.

We say it a lot here at Ambi, but what does it mean to “handle more?”

John: It’s our company mantra, which means using the technology we have to help people work smarter to take on excess burdens, combat monotony, and even eliminate some of the physical challenges of the day-to-day work that goes into sorting.

Joe: We don’t see our systems replacing people. There are not enough people out there, and there certainly aren’t people who want to do work that is taxing on the body. We are enabling the core group of people at these facilities to continue to do good work. We empower them to handle the extra volume with less stress and less wear and tear on the body.

Ready to Handle More?

At Ambi Robotics, we’re committed to delivering dynamic solutions customized to evolve alongside your business. We engineer our adaptable robotic solutions to optimize your operations, continuously ensuring peak efficiency and effectiveness. Ready to experience the ease of efficiency? Get in touch with our team today.