IN THE NEWS

Ambi Robotics Expands Partnership with Pitney Bowes To Automate Middle-Mile Sorting

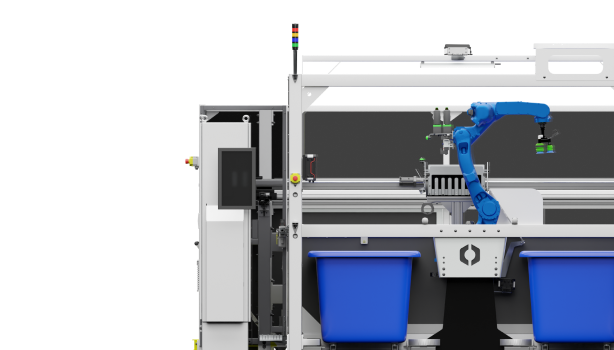

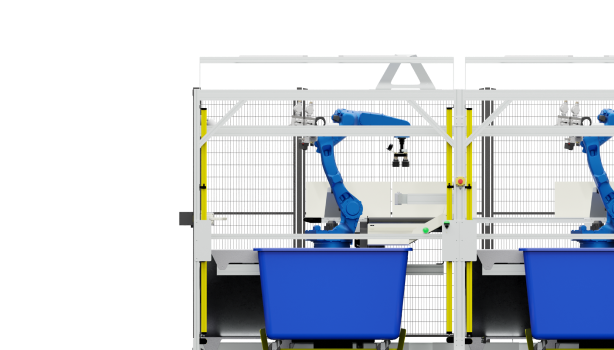

Ambi Robotics, a provider of artificial intelligence (AI)-powered robotic sorting solutions for supply chain operations, and Pitney Bowes Inc., global shipping and mailing company that provides technology, logistics, and financial services, today announced the successful deployment of the new AmbiSort B-Series modular parcel induction and sorting solution for middle-mile operations. This collaboration between two industry leaders advances ecommerce and logistics operations through cutting-edge automation and emerging technologies, the companies said.

Following the deployment of the AmbiSort A-Series small parcel sortation systems for last-mile operations, Pitney Bowes and Ambi Robotics partnered to develop and deploy the AmbiSort B-Series solution in Pitney Bowes ecommerce hubs across the U.S. The AI-powered robotics will help Pitney Bowes speed parcel sortation to middle-mile delivery providers, while improving productivity, accuracy, and worker safety.

“The successful deployment of the AmbiSort B-Series is a result of strategic and collaborative innovation between the two companies,” said Jim Liefer, CEO of Ambi Robotics. “Pitney Bowes is pioneering the future of smart logistics and has been at the forefront of transforming warehouse work to align with the demands of constant ecommerce. This partnership serves as a model of such collaborative innovation and sets a high bar for future supply chain modernization.”

As parcel volume exceeds 161 billion annual parcels globally, as revealed in the latest Pitney Bowes Parcel Shipping Index, logistics and global delivery organizations continue to seek automated solutions that can quickly scale to meet their unique needs.

“Today’s ecommerce demands must be met with speed, and as such, technological solutions must be scaled quickly. At Pitney Bowes, we are partnering with some of the most innovative companies in the industry to make B2C ecommerce logistics easier for our clients,” said Stephanie Cannon, SVP of Operations Excellence and Collaborative Innovation at Pitney Bowes. “With Ambi Robotics, we were able to develop a sortation system that solved a particular need and scaled it quickly across our ecommerce hubs, adding capacity for our clients ahead of peak season.”

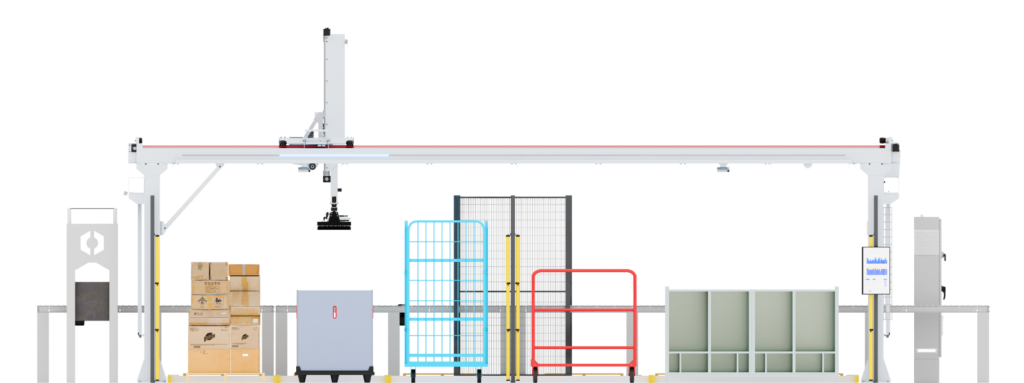

The AmbiSort B-Series improves sorting operations while reducing operating costs by inducting and sorting parcels into gaylord destinations and addressing the challenges of labor-intensive manual sorting throughout high-speed supply chain operations. The AmbiSort B-Series solution adapts to various use cases, such as reverse logistics, interfacility sortation, sort-to-carrier, zone-skipping, and automated parcel induction, the partners added/

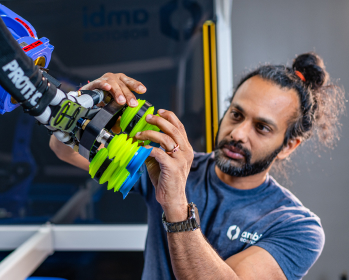

“We view automation as the execution of the undesirable tasks that humans don’t want to do so that employees can build a sustainable career. We achieve this by elevating the working conditions, setting the new standard of human work, and creating new desirable roles like robot operator and super robot operator,” said Ryan Hannon, VP of Industrial Engineering and Collaborative Innovation at Pitney Bowes.

This video provides an overview of the project and its aims. Additionally, Modern recently featured the use of multiple technologies at Pitney Bowes in a June cover story that provides an in-depth look at the modernization. Read the coverage here.