Blog

How Humans and Robots Work Together To Forge A Resilient Supply Chain

When a new crisis arises, the supply chain becomes a focus of the economy. The 2020 global pandemic due to COVID-19 was no exception. In fact, the entire world watched the United States supply chain while dependending on the network’s performance for timely and efficient deliveries. Resilience and agility for distribution and fulfillment operations is more important than ever. The supply chain never takes a break, but for health and safety reasons, humans were required to do just that during the pandemic – take a break.

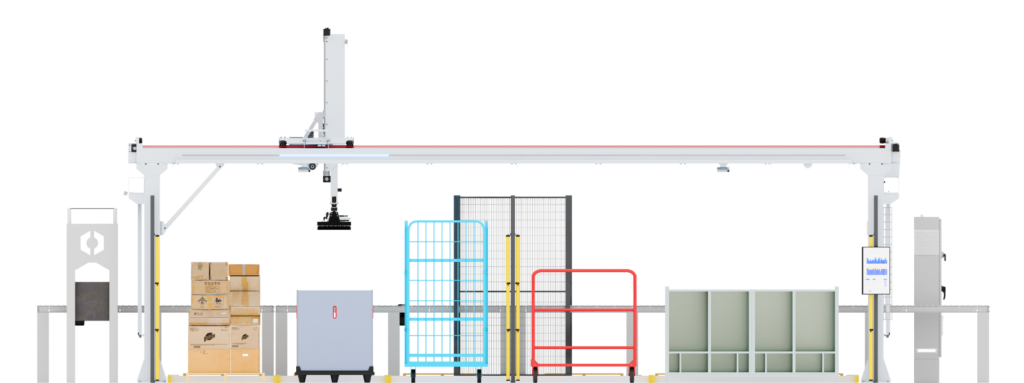

When the world shuts down, our supply chain must keep moving. How is this possible? The answer: AI-powered robotics systems that adapt and scale to meet demand.

The warehouse job is not what it used to be

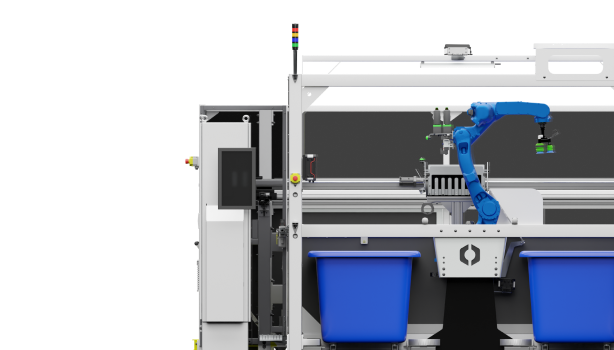

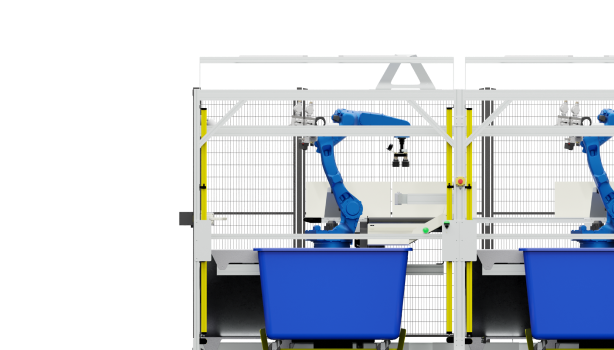

AI-powered robotics has reimagined the way humans perform their jobs in logistics and fulfillment operations. With automated systems augmenting the monotonous and repetitive tasks, the human workforce is now able to focus on more complex activities and contribute to innovative solutions in the warehouse. When teams are free to focus on value-added, rewarding, and stimulating tasks, associates feel valued and challenged, which increases productivity1, retention, and performance.

Automation improves efficiency and speed for high-volume operations

Companies can upskill their workforce into collaborative roles to focus on high-strategy efforts that cannot be automated by deploying robots to tackle the mundane, repetitive, lower value tasks.

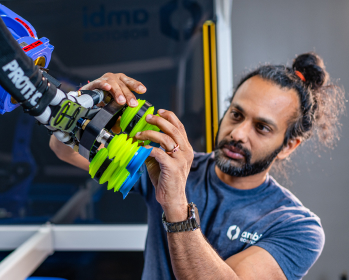

“We aim to bring humans and robots closer together to create a more efficient workplace. When employees are equipped with the tools that allow them to perform at their best, they become more engaged at work. We have witnessed workers admiring the technology and expressing that they feel valued, and our customers report this leads to increased retention. There is a great sense of company appreciation when equipped with industry-leading automation that allows you to work at your best.”

Joe Ruck, VP of Marketing at Ambi Robotics

Robots do not eliminate jobs, they allow humans to complete more fulfilling meaningful work

Automation is adopted naturally, at the pace of society’s acceptance and desire. If humans want to work a specific job, that job will always be there for the human. Technologies are naturally adopted where and when they are needed most. There is a reason AI-powered robotic systems are deployed for pick and pack operations. These tasks are difficult to hire and retain workers because they are very simple. In some cases these repetitive tasks lead to physical distress or injuries and can lead to departure of the human worker.

Let’s juxtapose our supply chain robotic systems to a well-adopted and highly leveraged consumer-facing piece of tech, the ATM. As the number of ATMs in the US continues to increase, so does the number of bank tellers. How does that happen? While the number of bank tellers per branch might decrease, banks can actually open more branches across the country due to increased profits and employee productivity thanks to the use and adoption of ATMs. Like with warehousing, the teller is now able to provide a more personalized experience to each customer while the ATM handles the mundane tasks of deposits and withdrawals. Tellers are now performing higher-skilled tasks that are best performed by human workers, and are no longer spending much of their time counting and distributing money.

I want to deploy AI-powered robots, but where do I start?

Many companies have remained comfortable operating for years with legacy systems. The global pandemic accelerated the adoption of automated systems to maintain reliable and consistent supply chain operations. Companies that are slow to adopt new technologies fall quickly behind their competitors. Many businesses are already playing catch-up from the impact of COVID-19, both with their own business and amongst their competitors.

Here are four steps to get your business closer to a resilient supply chain operation:

- Identify pain-points in your supply chain that are fraught with mundane, repetitive tasks

- Be open to modifying your existing workflow to integrate autonomous solutions

- Ask yourself, “Would I be happy performing this task?” If the answer is “No,” then automate it. Your employees likely feel the same way.

- Look for a provider that wants to understand your problem and work with you to configure a solution that is right for your unique business.

Resources

1http://www.smf.co.uk/wp-content/uploads/2015/10/Social-Market-Foundation-Publication-Briefing-CAGE-4-Are-happy-workers-more-productive-281015.pdf#page=9

Related Articles

-

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations.

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations. -

Blog | 11.22.2024AI-Powered Robots Deliver Reliable Performance During Peak Holiday Shipping SeasonDiscover how AI-powered robots revolutionize peak holiday season with enhanced speed, accuracy, and cost savings year over year.

Blog | 11.22.2024AI-Powered Robots Deliver Reliable Performance During Peak Holiday Shipping SeasonDiscover how AI-powered robots revolutionize peak holiday season with enhanced speed, accuracy, and cost savings year over year. -

Blog | 07.17.2024Interns of Ambi Robotics, Summer 2024 EditionMeet Ambi Robotics' Summer 2024 interns! Discover how these curious minds are innovating in AI-powered robotics and supply chain solutions.

Blog | 07.17.2024Interns of Ambi Robotics, Summer 2024 EditionMeet Ambi Robotics' Summer 2024 interns! Discover how these curious minds are innovating in AI-powered robotics and supply chain solutions.