IN THE NEWS

Pitney Bowes Taps New Ambi Robotics System For Middle-Mile Sortation

Dive Brief:

- Pitney Bowes is using a new parcel induction and sortation system from Ambi Robotics at e-commerce hubs to boost sorting speeds to middle-mile delivery providers, the companies announced Oct. 10.

- Pitney Bowes has deployed four of the AmbiSort B-Series systems in its network so far, Stephanie Cannon, Pitney Bowes’ SVP of operations excellence and collaborative innovation, said in an interview. The shipping and mailing company’s Monroe Township, New Jersey, facility and Ontario, California, hub each have two systems.

- “They’ve only been deployed for about four months now, and we’re over 3 million parcels already in terms of their sortation volume,” Ambi Robotics CEO Jim Liefer said in an interview about Pitney Bowes’ operations.

Dive Insight:

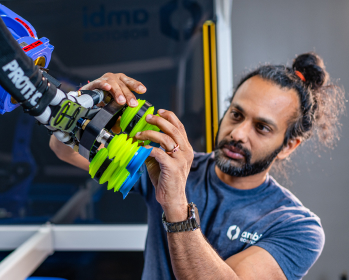

The B-Series deployment adds another milestone to Pitney Bowes and Ambi Robotics’ ongoing partnership.

Pitney Bowes announced plans in 2021 to use automated parcel sorting systems from Ambi Robotics for its Global Ecommerce business. After a successful deployment at a Stockton, California, facility, the two companies launched a $23 million expansion plan in 2022 to install last-mile sortation systems at hubs throughout the U.S.

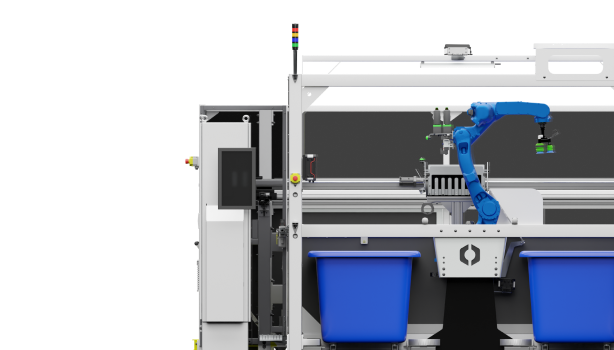

The new Ambi Robotics system using robotic arms allows Pitney Bowes to reduce its reliance on manual labor for sortation in its middle-mile operations, or the process of moving parcels from one facility to another.

While a human sorter can handle around 275 to 300 parcels an hour, the B-Series sorts about 1,250 parcels per hour for Pitney Bowes, Cannon said. This helps Pitney Bowes move parcels out of its facilities and onto trucks faster while minimizing sortation mishaps.

“When a manual sortation happens, they have the opportunity to mis-sort those parcels,” Cannon said. “A robot, when it’s inducting it through an automated process, will be less likely to mis-sort that parcel, so we have better service to the customers there.”

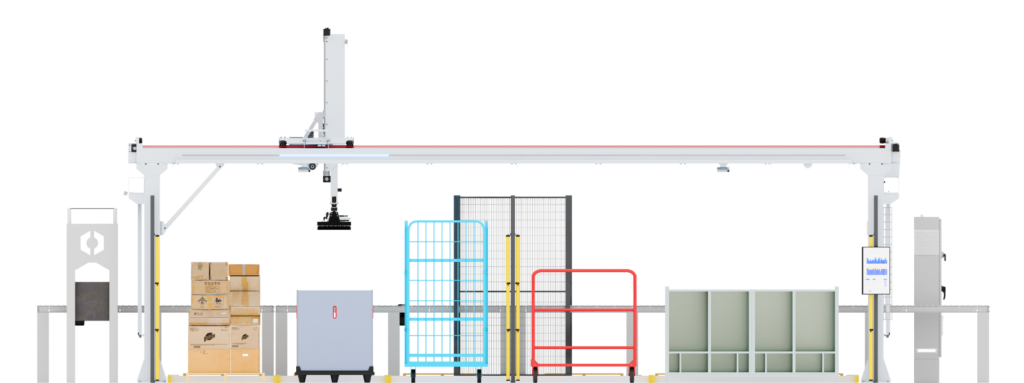

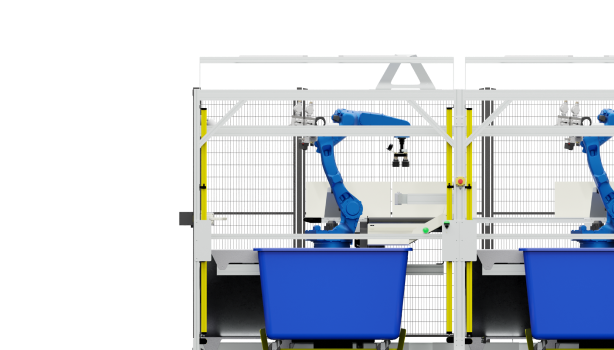

Ambi Robotics customers can configure the B-Series system to fit their specific sorting needs. For example, they can add more induction cells to increase throughput or expand the number of destinations to boost capacity, according to a June news release from Ambi Robotics.

The system can also adapt to use cases such as interfacility sortation, zone skipping and reverse logistics, which will come in handy during the post-holidays returns rush.

“We’re coming into holiday right now, and then just on the other side of that peak, the volume shifts over to the returns side,” Liefer said. “We’re happy to have that kind of modularity for the system.”