IN THE NEWS

Power Grab

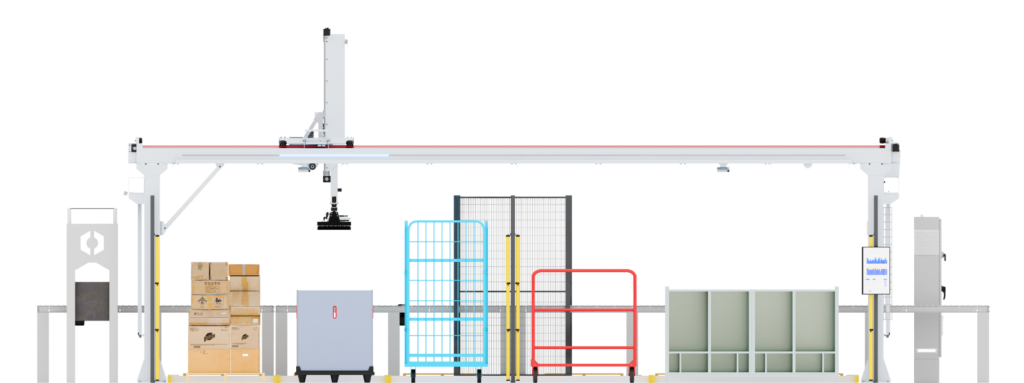

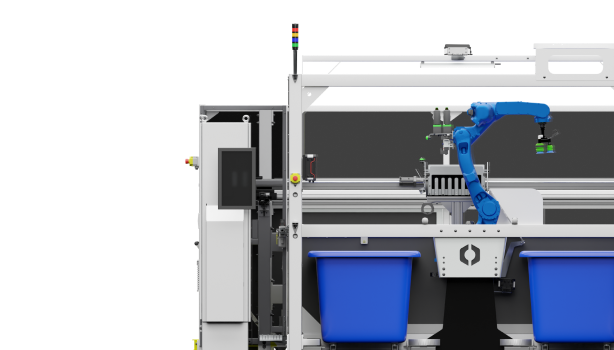

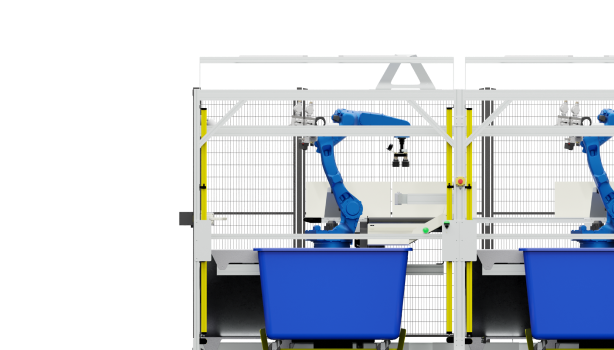

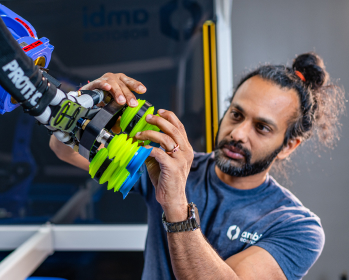

Startup Ambi Robotics is building and deploying (via an undisclosed customer in production) AmbiSort, an enclosed, industrial robot. It can sort through items in a bin, scan them and place them on a gantry to be stowed for last-mile journeys – and do it twice as fast as traditional manual picking.

In other words, “the era of state-of-the-art parcel sorting technology is upon us, finally, for real,” said the company’s just-installed CEO Jim Liefer.

Ambi, he explained, was born out of research begun just a few years ago in a lab at UC Berkeley. With $6 million in seed funding (led by Bow Capital), the company is already deploying AI-powered robotic systems to solve for real-world supply chain chokepoints – within chains that have been pushed to the limit amidst a profound shift in consumer behavior with respect to ordering everything, online.

“The operational challenge faced by distribution centers has been, for years, ‘how in the world do we deal with all of these small items?'” explained Liefer in an exclusive interview with Forbes.com right after the company announced his arrival on March 31.

The fact that Ambi’s progress has come so fast owes in large part to “simulation-to-reality AI” training that allows the automated sorting system to accumulate years’ worth of knowledge, about the shapes of things and surroundings, in mere hours.

At Ambi, the vision quest driving their mission was to build something that put function ahead of form; small enough (13 feet x 23 feet) to fit into a distribution center sortation area but big and fast enough to double throughput rates.

These systems, built with customers’ needs at the fore, have an industrial look about them. Fit for a warehouse but not designed for a marketing campaign, Ambi’s new leader concedes.

“Our robots don’t dance,” Liefer said. “But they work.”