IN THE NEWS

Exclusive: This is the Most Dexterous Robot Ever Created

The most nimble-fingered machine yet shows how machine learning can teach robots to recognize and pick up different types of objects, a skill that could transform many factories and warehouses.

It might not look that special, but the robot above is, according to a new measure, the most dexterous one ever created. Among other tricks, it could sort through your junk drawer with unrivaled speed and skill.

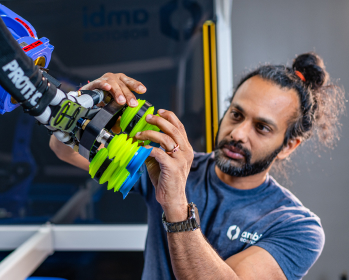

The key to its dexterity is not in its mechanical grippers but in its brain. The robot uses software called Dex-Net to determine how to pick up even odd-looking objects with incredible efficiency.

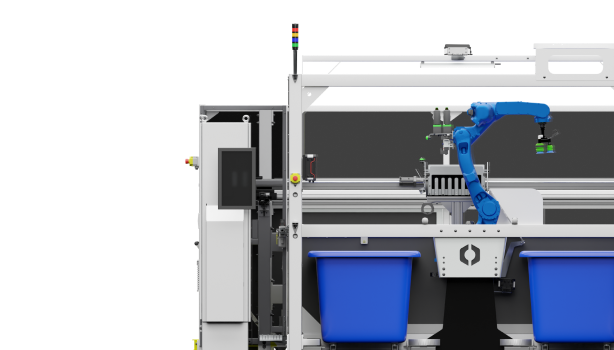

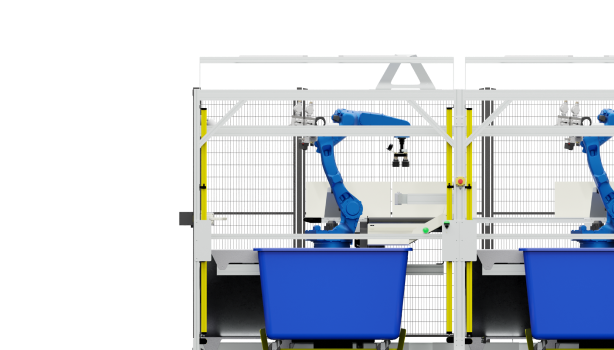

Dex-Net was developed by Ken Goldberg, a professor at UC Berkeley, and one of his graduate students, Jeff Mahler. The software runs on an off-the-shelf industrial machine made by ABB, a Swiss robotics company. Goldberg demonstrated the latest version of his system at EmTech Digital, an event in San Francisco organized by MIT Technology Review and dedicated to artificial intelligence.

Goldberg’s system is a lot closer to matching the adroitness of a human than anything developed previously. Industrial robots with better dexterity could find application in warehouses and factories as well as hospitals and homes.

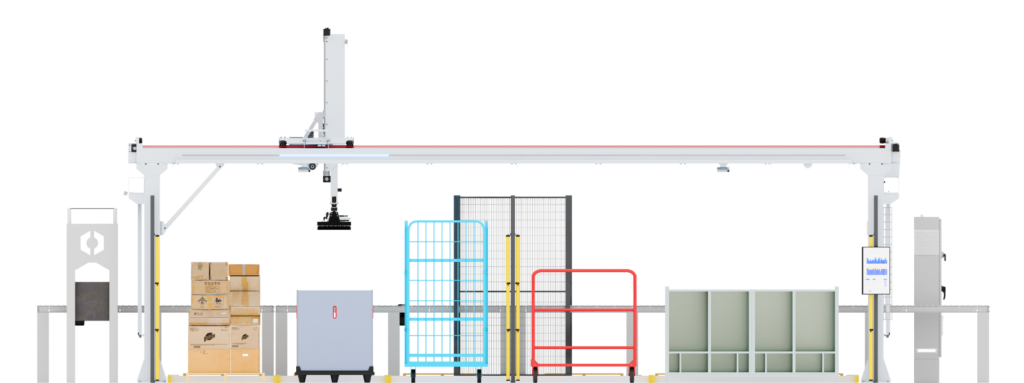

What’s especially clever about Dex-Net is how it learns to grasp. The software tries picking up objects in a virtual environment, training a deep neural network through trial and error. Even in simulation, this is a laborious task. Crucially, though, Dex-Net can generalize from an object it has seen before to a new one. The robot will even nudge an item to get a better look at it if it isn’t sure how it should be grasped. The latest version of the system includes a high-resolution 3-D sensor and two arms, each controlled by a different neural network. One arm is equipped with a conventional robot gripper and another with a suction system. The robot’s software scans an object and then looks at both neural networks to decide, on the fly, whether it makes more sense to grab or suck that particular object.

UC Berkeley researchers also developed a better way to measure the performance of a picking robot: a metric called “mean picks per hour,” which is calculated by multiplying the average time per pick and the average probability of success for a consistent set of objects.

The new metric will help research labs working on picking robots share their results. “We’ve been talking about how to align our results so that we see progress,” Goldberg says. “It all depends what robot you’re using, what sensor you’re using, and—very importantly—what objects you’re using.”

-

Ken Goldberg, photo by Jeremy Portje

Humans are capable of between 400 and 600 mean picks per hour. In a contest organized by Amazon recently, the best robots were capable of between 70 and 95. The new machine reaches 200 to 300 mean picks per hour, Goldberg says. The results will be presented at a conference in Australia later this year.

…