Blog

Prime Day Is Now a Four-Day Spectacle And One Million Robots Are Running the Show

It’s been a decade of deals, delivered right to your door.

Ten years ago, Prime Day was just a 24-hour birthday sale.

Today, it’s a 96-hour, $24 billion retail juggernaut, twice the size of Black Friday, running in the middle of July. Adobe Analytics is calling it the biggest sales week of the year. And it’s only getting bigger.

Last week, Amazon crossed the one million robot milestone in its global network.

“These robots work alongside our employees, handling heavy lifting and repetitive tasks while creating new opportunities for our front-line operators to develop technical skills,” says Scott Dresser, Vice President of Amazon Robotics. “I’m particularly proud that since 2019, we’ve helped upskill more than 700,000 employees through various training initiatives, many focused on working with advanced technologies.”

And it’s enabled Prime Day to go from one day… to four.

The Sales Are Big. The Real Story Is Bigger.

Behind every deal that makes you smile, there’s a warehouse operating at full tilt. Customer orders picked, packed, and shipped in minutes. What used to take hours now happens in seconds, without the strain of supply chain demand resting on the shoulders of people.

VP of Amazon Robotics, Joseph Quinlivan recently said, “Robotics is about using technology to better deliver for our customers, empower people, create opportunities, and build a safer, more efficient, and sustainable workplace—making it an attractive place for those who want to shape the future.”

He’s right. It’s not about fewer jobs. It’s about better tools. Better workflows. Better results. It’s all about “Empowering people to handle more.”

In a recent Amazon newsroom article , the company writes: “Supporting our employees’ career growth isn’t just a priority—it’s a cornerstone to our philosophy. In keeping with our commitment to help employees pursue more skilled and higher-earning roles, Amazon is announcing it has upskilled over 700,000 Amazon employees globally, including front-line hourly employees in fulfillment centers and delivery stations.”

And when the tools get better, so does the work.

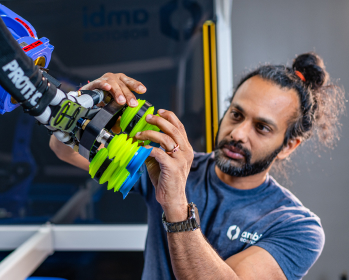

Today’s robotic systems aren’t just faster, they’re getting smarter with each use. And so are the people using them, learning to unlock new levels of productivity with AI-powered robotic tools and technology.

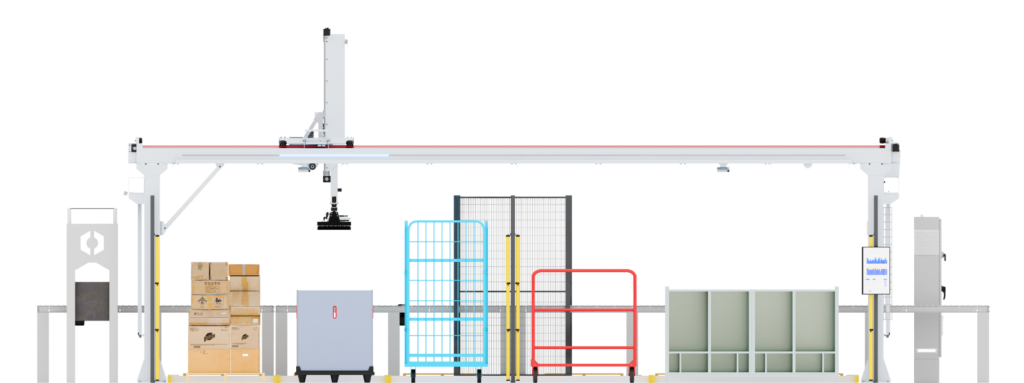

Enabled by breakthroughs in AI, robots have evolved from sorting generic boxes to handling real-world chaos and complexity. AmbiSort, for example, can now sort products directly in their original manufacturer’s packaging, eliminating the additional box, bag, or envelope. Less packaging means more room in every vehicle, enabling trucks to carry more, with fewer trips.

It’s the smarter way to ship: Less waste, better truck utilization to the final-mile, and lower costs. And this is at a massive scale, serving more than 300 million active customers worldwide, including 180 million active Prime members.

Thinking Outside the Box for Smarter Shipping.

Amazon is on a mission to eliminate packaging altogether. In 2023, 12% of orders were shipped without any Amazon packaging, just a label slapped on the product’s original box. It’s called “Ships in Product Packaging.”

Since 2015, Amazon has reduced packaging weight per shipment by more than 43%, avoiding over 3 million metric tons of waste. That’s 285 Space Needles worth of cardboard, plastic, and foam, gone.

But here’s the kicker: you can’t do that kind of shipping with legacy automation. Most warehouse robots can’t tell the difference between a toothbrush and a toaster when they’re not wrapped in uniform boxes. Robots need consistency. Product packaging doesn’t give them that.

It takes a lot of data to solve this challenge.

New AI Skill in AmbiOS: “Sorts In Product Packaging”, Powered by PRIME-1

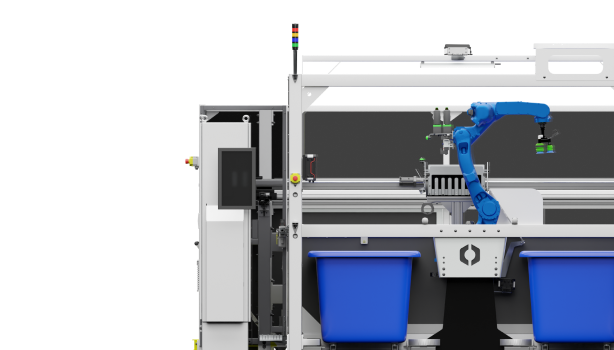

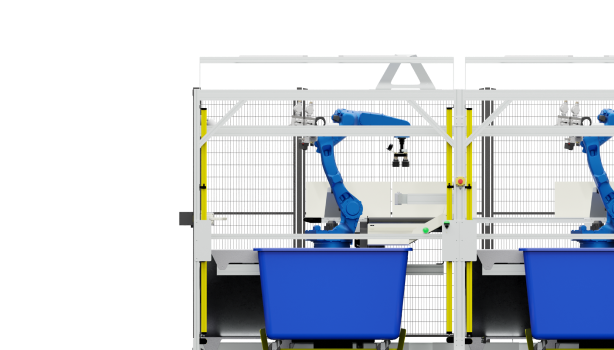

Today, we’re proud to share that Ambi Robotics has made “Sorts in Product Packaging” a reality with AmbiSort, powered by AmbiOS and our proprietary AI foundation model, PRIME-1.

Here’s the problem we solved: Sorting items in their original packaging used to be a nightmare for robots. No uniform dimensions. No predictable grip points. No standardized surfaces. But with PRIME-1, AmbiSort can now recognize, grasp, and sort a staggering range of SKUs, directly in their original packaging. No repacking. No relabeling. Just grab, scan, and ship.

“Our customers are pushing toward a future with less waste and more efficient operations,” said Jim Liefer, CEO of Ambi Robotics. “PRIME-1 makes that future possible by enabling AmbiSort to handle the diversity of real-world products, directly in their original packaging.”

Primed and Ready: Sustainability On Autopilot

For Fortune 500 retailers under pressure to hit sustainability goals while keeping up with demand, this is a big moment. What used to be a choice, efficiency or sustainability, is now a both/and.

With AmbiSort and PRIME-1, warehouse operators can now autonomously:

- Sort products in original packaging, without adding extra bags or boxes

- Increase truck fill rates (less air, more goods)

- Reduce packaging costs and waste

- Keep up with surging ecommerce volume without adding manual tasks

And most importantly, they can do all of this at scale.

The Robots Behind “Buy Now”

No one’s putting robots on billboards and banners…yet. They’re not the face of Prime Day. But they are the reason it works.

The smarter your systems, the faster your operations. And the companies winning this race? They’re investing in AI-powered tools built to handle the real world chaos, not just packing boxes into bigger boxes, like Russian dolls.

Legacy automation assumes every order looks the same. But today, customers shop from A to Z, from anywhere, anytime they want.

So while shoppers click “Buy Now,” a new kind of supply chain has already clicked into place. This one is built for speed, sustainability, and SKU diversity.

Knock knock.

When your Prime Day order arrives without an extra box, now you’ll know it’s more than a win for the planet. It’s a knock, reminding us that we’re creating a more sustainable supply chain. Working smarter, safer, and always putting people first.

Because behind every robot and every box saved is a person. People are learning new skills, working with smarter tools, and shaping a future where AI-powered robotic tools empower them to handle more than ever before.

And for the record. Yes, your order really did arrive in its birthday suit.

Happy Birthday, Prime Day. You’ve turned summer into the new peak season in just a decade. Here’s to what’s next!

Related Articles

-

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations.

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations. -

Blog | 01.09.2024Ambi Robotics Achieves Unmatched Autonomous Sorting Speeds with NVIDIA GPUs and Accelerated Computing

Blog | 01.09.2024Ambi Robotics Achieves Unmatched Autonomous Sorting Speeds with NVIDIA GPUs and Accelerated Computing -

Blog | 06.30.2019Grasping the Future: The Ambi Robotics JourneyIt begins as all good stories do. Some dead robots in a basement, an unrivaled group of experts, an old turntable, and a desire to create something meaningful. The result? Ambi Robotics, a company centered on empathy and focused on efficiency.

Blog | 06.30.2019Grasping the Future: The Ambi Robotics JourneyIt begins as all good stories do. Some dead robots in a basement, an unrivaled group of experts, an old turntable, and a desire to create something meaningful. The result? Ambi Robotics, a company centered on empathy and focused on efficiency.