IN THE NEWS

Ambi Robotics Deploying Parcel Sorting Robots at OSM Worldwide Warehouses

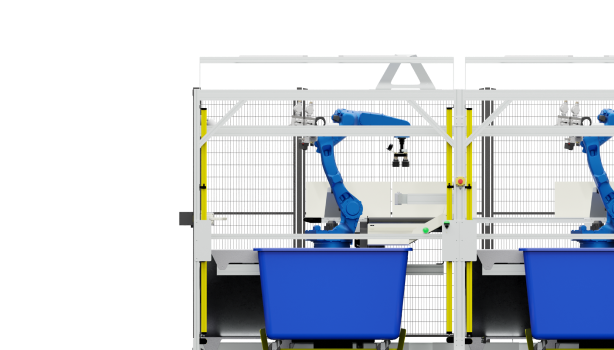

Ambi Robotics is deploying its parcel sorting robots at OSM Worldwide’s warehouses in the U.S. Based on the minimum four-year robots-as-a-service (RaaS) deal, the flagship AmbiSort A-Series system will be installed at OSM warehouses in Atlanta, Chicago, and Las Vegas.

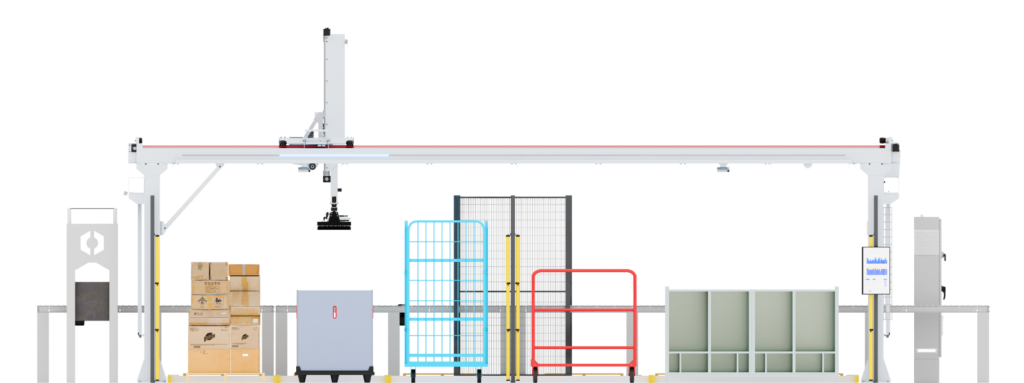

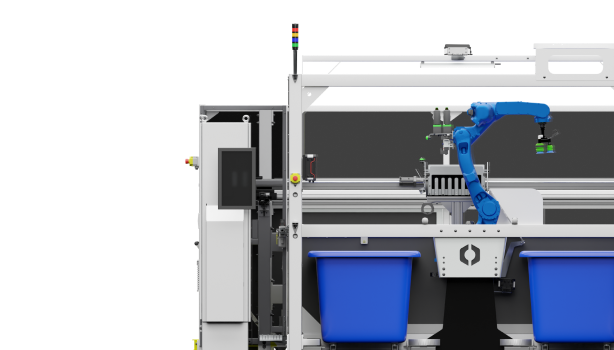

The AmbiSort A-Series is a configurable robotic sorting system that uses machine learning to adapt to mixed parcels like polybags, flats and boxes into last-mile mailsacks. The systems are modular and configurable to accept parcels via rolling bin or the new conveyor-fed automated induction system.

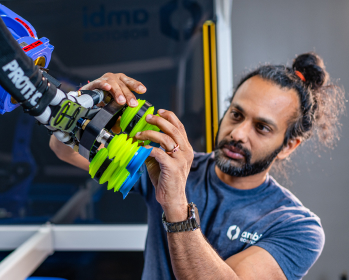

AmbiSort is powered by AmbiOS, the company’s proprietary operating system that leverages simulation-to-reality (Sim2Real) artificial intelligence (AI). AmbiOS is based on The Dexterity Network (Dex-Net) project that was developed at UC Berkeley to automate the training of deep neural networks to improve a robot’s ability to grasp various items. Many of Dex-Net’s developers are now working at Ambi Robotics.

According to Ambi Robotics, AmbiSort systems are first designed and trained in simulation, which speeds up training 10,000x faster than teaching algorithms in the physical world.

“At OSM Worldwide, we are always looking for ways to improve our sorting and delivery operations, and we’re excited to partner with Ambi Robotics to empower our workforce with cutting-edge technology across our warehouses,” said James Kelley, president at OSM Worldwide. “With the AmbiSort A-Series systems, we can improve order accuracy and speed to our ecommerce customers while improving efficiency and safety for our warehouse employees amid rising parcel demand.”